AR-15, Bolt carrier Groups

The Bolt Carrier Group: The Cornerstone of a Hard-Use AR-15

Table of Contents

When assembling an AR-15 intended for rigorous use—whether facing high round counts, harsh conditions, or sustained reliability demands—the bolt carrier group emerges as the foundational component. It drives the rifle’s operation, managing the critical sequence of locking, unlocking, extracting, ejecting, and chambering rounds. A subpar bolt carrier group risks undermining the entire system, while a robust one ensures performance under pressure. For a hard-use rifle, durability is paramount, as the bolt carrier group must withstand internal pressures of 50,000 to 60,000 PSI, depending on the load, and endure thousands of cycles without faltering. This analysis explores what defines a Mil-Spec bolt carrier group, identifies key attributes for hard-use applications, explains why cost-cutting here is inadvisable, and examines Dirty Bird Industries’ offering as an example.

Understanding “Mil-Spec”: A Baseline, Not a Guarantee

“Mil-Spec” refers to Military Specification, a standard set by the U.S. military to ensure components like the bolt carrier group perform reliably in combat. This encompasses precise materials, tolerances, heat treatments, and testing protocols. A Mil-Spec bolt is forged from Carpenter 158 steel, shot-peened, subjected to high-pressure testing (HPT), and inspected via magnetic particle inspection (MPI). The carrier is machined from 8620 steel, heat-treated, and coated with manganese phosphate, while gas keys are secured with staked Grade 8 fasteners. In the commercial market, however, “Mil-Spec” varies in application. Some manufacturers use it as a loose marketing term for minimally compliant parts, while others adhere strictly or exceed the standard. ARBuildJunkie.com notes that Mil-Spec represents a proven baseline—sufficient for military service but requiring evaluation to meet the demands of a hard-use civilian rifle. It is a starting point, not the ultimate measure of quality.

More on Mil-Spec

The term “Mil-Spec” denotes a military standard designed to ensure weapon system components, such as the bolt carrier group, meet exacting requirements for reliability and interoperability in combat. However, its application in the civilian market often breeds confusion. While Mil-Spec outlines precise specifications—such as Carpenter 158 steel for bolts and rigorous testing protocols—some manufacturers exploit the label, offering parts that barely meet the minimum threshold or fail to uphold the intended quality. True Mil-Spec adherence reflects a commitment to standards that have been refined through extensive military use, yet it remains a baseline rather than a pinnacle. For a hard-use AR-15, understanding this distinction is critical, as not all “Mil-Spec” bolt carrier groups deliver the durability demanded by punishing conditions.

Materials: The Foundation of Reliability

The resilience of a bolt carrier group begins with its materials. The bolt requires Carpenter 158 steel, a chrome-nickel alloy with tool steel strength, designed to endure the extreme pressures—up to 60,000 PSI—of chambering and extraction. Alternatives like 9310 steel appear in some bolt carrier groups, but deviating from Carpenter 158 demands rigorous validation to ensure comparable performance over the long haul. Shot-peening, which compresses the steel’s surface to mitigate stress fractures, is essential for longevity. The carrier, typically 8620 steel, provides a durable, heat-treatable foundation that pairs effectively with phosphate coatings to resist wear and corrosion. The gas key, made from 4130 chromoly steel, relies on Grade 8 screws, torqued and staked to maintain gas system integrity. These Mil-Spec materials have proven their reliability through extensive use, making them the benchmark for a bolt carrier group intended for sustained, high-volume operation. Inferior substitutes jeopardize durability, especially under punishing firing schedules.

Testing: Validation Under Pressure

A bolt carrier group’s ability to perform must be proven through testing. Mil-Spec mandates High-Pressure Testing (HPT), exposing the bolt to a proof load exceeding standard pressures, followed by Magnetic Particle Inspection (MPI) to detect microscopic flaws using magnetic fields and fluorescent particles. Bolts passing both are marked “HP” and “MP.” Reputable manufacturers test each bolt individually, avoiding less stringent batch sampling. For a hard-use rifle, this level of scrutiny is critical. Some producers enhance reliability by cycling assembled bolt carrier groups through full-auto fire or with underpowered ammunition to identify weaknesses. A bolt carrier group lacking such validation may suffice for casual shooting but risks failure under the sustained stress of thousands of rounds—a compromise that undermines a rifle built for the long term.

Critical Details: Staking, Springs, and Components

The effectiveness of a bolt carrier group depends on meticulous attention to its smaller elements. Gas key staking is a prime example: Grade 8 screws must be torqued to 55-60 inch-pounds and staked securely, with metal displaced into the screw heads to prevent loosening. Inadequate staking can disrupt the gas system, leading to cycling failures. Buyers should confirm this detail through inspection or detailed product descriptions. Springs and pins also require precision. The extractor spring must maintain consistent tension to remove spent casings, while the ejector spring ensures reliable ejection—both should meet or exceed Mil-Spec standards for strength and corrosion resistance. The firing pin, often enhanced with a hard-chrome finish, improves durability and ignition reliability. These components, though minor, are integral to a bolt carrier group’s performance under demanding conditions.

Coatings: Balancing Durability and Functionality

Mil-Spec bolt carrier groups feature manganese phosphate coatings, valued for retaining lubrication, resisting corrosion, and withstanding carbon buildup. This finish excels in harsh environments, making it a cornerstone for hard-use applications. Chrome-lined carriers offer reduced friction and simpler maintenance, providing an edge in extreme scenarios. Advanced coatings like Nickel Boron or Diamond-Like Carbon (DLC) deliver superior lubricity and ease of cleaning, though their benefits for hard-use rifles are debated. They may not retain lubrication as effectively as phosphate over prolonged field use, a key factor for rifles exposed to dirt or moisture. Functionality, not aesthetics, should dictate the choice of coating.

Why You Should Never Skimp on the Bolt Carrier Group

Cost-cutting on the bolt carrier group is a critical misstep for a hard-use AR-15. A low-priced unit may function for casual range trips, but a rifle subjected to high round counts or adverse conditions demands uncompromising quality. A deficient bolt carrier group—whether from a cracked bolt, unstaked gas key, or weak spring—can halt operation, with consequences far outweighing initial savings. In contrast, a well-crafted bolt carrier group endures tens of thousands of rounds with proper care, delivering reliability where hobby-grade options falter. The bolt carrier group faces intense mechanical stress—pressures up to 60,000 PSI, heat, and friction—making it the linchpin of the rifle’s longevity. ARBuildJunkie.com reinforces this: components enduring the AR-15’s dynamics must be built for resilience. Investing here is not about excess; it’s about ensuring a rifle remains operational when pushed to its limits.

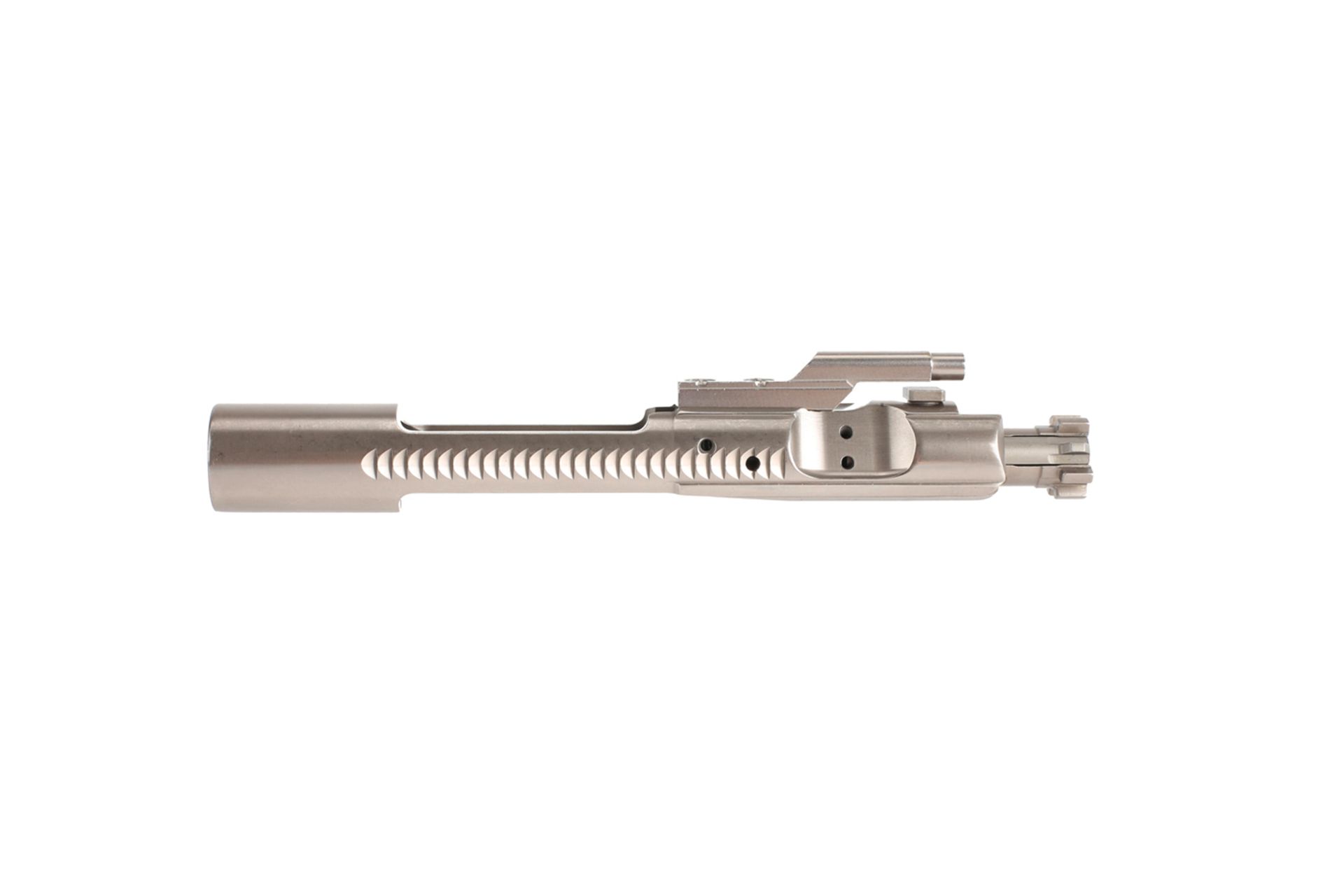

Spotlight: Dirty Bird Industries AR-15 Bolt Carrier Group

Dirty Bird Industries offers a bolt carrier group designed for shooters seeking Mil-Spec reliability with practical enhancements. Available at dirtybirdindustries.com, the Dirty Bird AR-15 Bolt Carrier Group features a Carpenter 158 steel bolt, heat-treated and shot-peened to Mil-Spec standards. The carrier, machined from 8620 steel, adopts a full-auto profile for added mass, enhancing cycling stability across various ammunition types and conditions, even in semi-auto configurations. The gas key is secured with Grade 8 fasteners, torqued and staked to prevent movement, and the bolt carrier group is coated with manganese phosphate for durability and lubricity. Each bolt undergoes HPT and MPI testing, ensuring no defects compromise performance. Priced competitively, this bolt carrier group balances Mil-Spec adherence with attention to detail, making it a viable option for hard-use builds. User reviews praise its reliability through thousands of rounds, affirming its capability.

Beyond materials and testing, Mil-Spec bolt carrier groups adhere to strict dimensional tolerances and functional requirements, ensuring compatibility and interchangeability with other Mil-Spec components. This standardization facilitates maintenance, repair, and part replacement in the field—a practical advantage for military applications that translates to civilian hard-use rifles.

Key Attributes of a Hard-Use Bolt Carrier Group

When selecting a bolt carrier group for a hard-use AR-15, prioritize these criteria:

- Materials: Carpenter 158 bolt, 8620 carrier, 4130 gas key—proven alloys with no untested substitutions.

- Testing: Individual HPT and MPI on every bolt, with additional stress testing as an advantage.

- Staking: Gas key fasteners torqued and staked securely, verifiable through inspection or documentation.

- Components: Mil-Spec or better springs and a durable, preferably hard-chromed firing pin.

- Coating: Phosphate for field-proven reliability, or chrome for enhanced performance.

- Profile: Full-auto weight for consistent cycling under adverse conditions.

These standards ensure a BCG can withstand the rigors of hard use without sacrificing reliability.

Conclusion: Invest in the Core

A hard-use AR-15 requires a bolt carrier group that matches its purpose—durable, reliable, and meticulously crafted. Mil-Spec establishes a trusted foundation: Carpenter 158 steel, rigorous testing, and robust construction. From there, options like Dirty Bird’s bolt carrier group or others you’ll feature can be evaluated, prioritizing quality over cost. The bolt carrier group is the rifle’s operational core; a wise investment here ensures it endures thousands of rounds, delivering performance when it matters most. Build with this in mind, and craft a rifle that lasts.