AR Parts and Accesories, AR-15, Bolt carrier Groups

AR-15 Bolt Carrier Groups: The Definitive Guide to Choosing the Perfect Component

Table of Contents

The bolt carrier group is the cornerstone of the AR-15, driving the essential functions of chambering, firing, extracting, and cycling rounds. Its performance under stress dictates the rifle’s reliability, making its selection a critical decision for shooters building or upgrading an AR-15, whether for recreational shooting, tactical operations, or competitive events.

At Dirty Bird Guns & Ammo, we understand the complexity of choosing the right bolt carrier group and aim to provide a comprehensive guide to empower informed decisions.

This definitive resource explores the bolt carrier group’s role, its components, key selection factors, specialized options like lightweight and adjustable gas designs, premium offerings like the LMT Enhanced Bolt Carrier Group, common errors from subpar units, installation and maintenance practices, and prevalent myths, ensuring shooters select a bolt carrier group that meets their rifle’s demands.

What Is a Bolt Carrier Group?

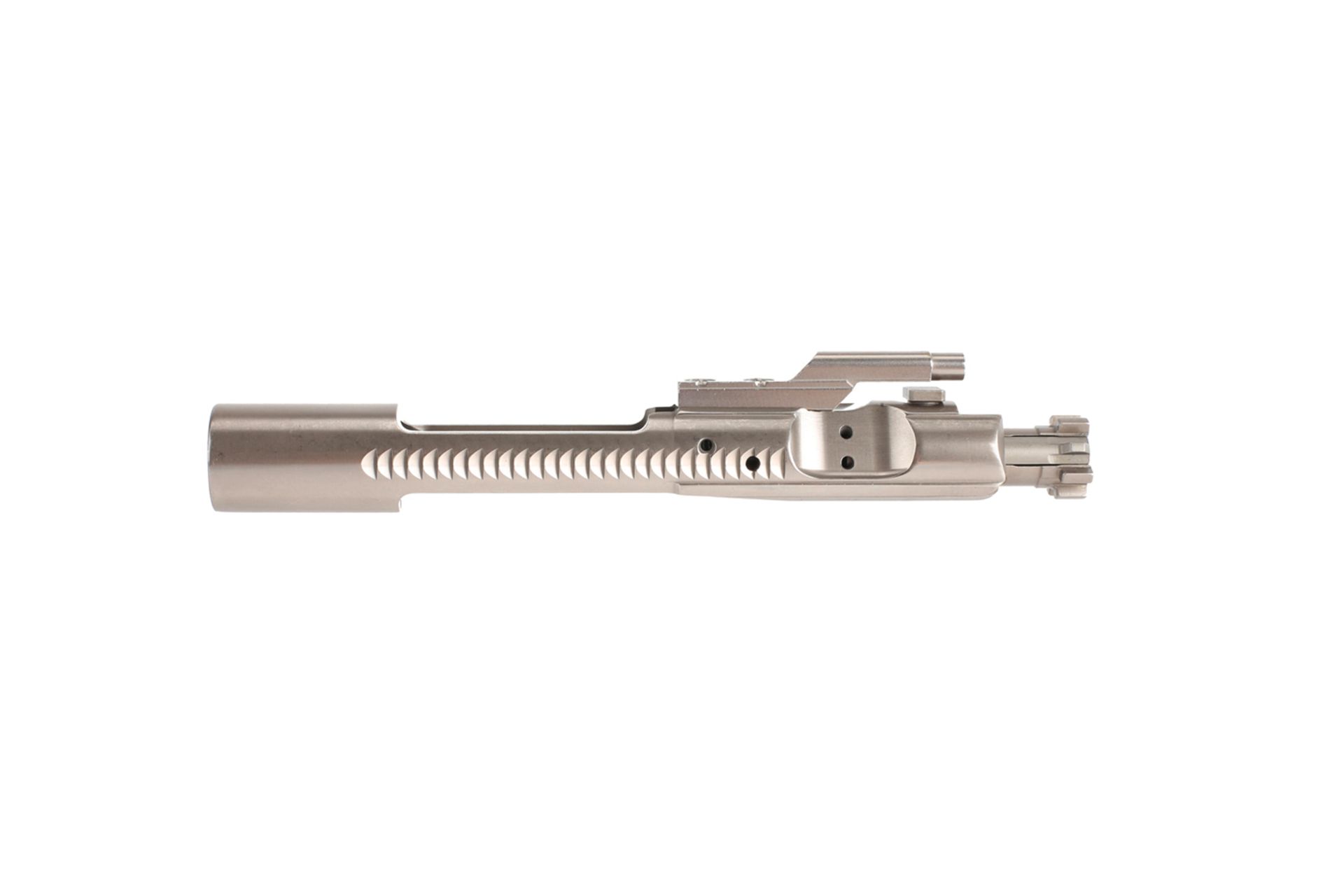

The bolt carrier group is a precision-engineered assembly within the AR-15’s upper receiver, enabling the rifle to fire and cycle reliably. It comprises several components that work together seamlessly:

- Bolt Carrier: A steel body that houses the bolt, interfaces with the upper receiver, and channels gas to drive the action.

- Bolt: Engages the barrel extension, chambers the round, locks for firing, and extracts spent casings.

- Firing Pin: Strikes the cartridge primer to ignite the propellant, initiating the firing sequence.

- Cam Pin: Rotates the bolt to lock or unlock it from the barrel extension and aids in extraction.

- Gas Key: Directs gas from the barrel into the bolt carrier group to cycle the action.

These components ensure the AR-15 operates effectively, making the bolt carrier group indispensable. A failure in any part, such as a cracked bolt or loose gas key, can halt the rifle, highlighting the need for a high-quality assembly.

Key Factors to Consider When Choosing an AR-15 Bolt Carrier Group

Selecting the optimal bolt carrier group requires careful evaluation to align with the rifle’s purpose and operating conditions. The following factors guide the decision-making process:

- Caliber Compatibility: The AR-15 supports various calibers, and the bolt carrier group must match the specific chambering to ensure proper function and safety. Most AR-15s are chambered in 5.56x45mm NATO or .223 Remington, which share the same bolt design as calibers like .300 AAC Blackout, .224 Valkyrie, 6.8 SPC II, and 6.5 Grendel. This compatibility allows a single bolt carrier group to support these rounds if the barrel and magazine are appropriate. Other calibers, such as 7.62x39mm, 9mm, or .450 Bushmaster, require a bolt designed for their larger case heads to handle increased extraction forces. Specialized calibers like .458 SOCOM or 6mm ARC may need unique bolts due to distinct case sizes or headspacing requirements. Using an incompatible bolt carrier group risks feeding, extraction, or safety issues, so shooters must confirm compatibility, with headspacing verified via go/no-go gauges for custom builds or non-standard calibers.

- Material and Construction: The choice of materials significantly impacts durability. Carpenter 158 steel, the Military Specification (Mil-Spec) standard for bolts, withstands pressures up to 60,000 PSI, offering proven reliability for high-stress applications. Alternatively, 9310 steel, when properly heat-treated, provides slightly greater fatigue resistance, making it a preferred choice for high-performance bolts. Carriers typically use 8620 steel, heat-treated for toughness and wear resistance, while gas keys employ 4130 chromoly steel to ensure a secure gas seal. Finishes protect against corrosion and wear. Phosphate coatings, a Mil-Spec staple, excel at retaining lubrication and resisting rust, ideal for rugged conditions. Nitride finishes enhance surface hardness, reduce friction, and simplify cleaning, offering a balance of durability and maintenance ease. Nickel boron finishes provide low friction but may not retain lubrication as effectively in dusty environments, requiring careful consideration based on operating conditions.

- Type of Bolt Carrier: Full-auto bolt carrier groups, weighing around 11.6 ounces, incorporate additional rear mass to enhance cycling stability, making them suitable for semi-auto rifles, particularly those with suppressors or short barrels. These are legal for civilian use and widely favored for reliability. Semi-auto bolt carrier groups, weighing around 11 ounces, are optimized for civilian rifles but may be less effective in over-gassed systems, where excess gas pressure can lead to cycling issues.

- Gas System Compatibility: The majority of AR-15s operate using a direct impingement system, where gas from the fired cartridge cycles the bolt carrier group, requiring a standard design. Piston-driven systems, which provide cleaner operation and reduced heat in the receiver, necessitate a bolt carrier group with a modified gas key to interface with the piston. Selecting a bolt carrier group that mismatches the rifle’s gas system can result in cycling failures or excessive wear.

- Weight and Balance: The weight of the bolt carrier group influences recoil and rifle balance. Standard weight bolt carrier groups, at approximately 11.5 ounces, are versatile for general use, offering a balance of reliability and cycling speed. Heavy bolt carrier groups, weighing up to 13 ounces, reduce recoil and enhance reliability with heavier ammunition or suppressors, making them ideal for tactical or short-barreled rifles. Low-mass bolt carrier groups, discussed further in the advanced considerations section, cater to specific performance needs.

- Bolt Material and Extractor Quality: The bolt must be constructed from high-quality steel, such as Carpenter 158 or 9310, to endure intense pressures. The extractor, responsible for removing spent casings, requires a robust spring and insert, such as a nitrile-butadiene buffer meeting Mil-PRF-6855 standards (80+/-5 durometer), to ensure consistent extraction, particularly in fouling-heavy calibers like 7.62x39mm. A weak extractor can lead to failures, compromising the rifle’s reliability.

- Headspace: Proper headspacing, the precise fit between the bolt and barrel, is essential for safe chambering and extraction. Most bolt carrier groups are pre-headspaced, but custom builds or non-standard calibers require verification using go/no-go gauges to prevent pressure spikes or extraction issues, which could result in dangerous malfunctions.

Advanced Considerations for Specialized Bolt Carrier Groups

Specialized bolt carrier groups cater to specific applications, offering tailored performance for unique needs. Understanding these options helps shooters optimize their AR-15 for particular scenarios.

Skeletonized and Lightweight Bolt Carrier Groups

Skeletonized or lightweight bolt carrier groups, weighing approximately 8 to 9 ounces, are engineered for performance-driven applications, particularly in competitive shooting disciplines like 3-gun or precision rifle matches. By removing material from the carrier through cutouts or scalloped designs, manufacturers like Faxon Firearms and JP Enterprises achieve lower mass while maintaining structural integrity. These bolt carrier groups are ideal for shooters seeking faster cycling and reduced recoil to improve split times between shots, enhancing speed and accuracy in competitions. They also benefit lightweight AR-15 builds, such as hunting rifles, where minimizing weight improves portability.

However, lightweight bolt carrier groups require careful tuning to function reliably. Without an adjustable gas block, they can over-cycle, leading to bolt bounce, premature component wear, or extraction failures, especially with high-pressure 5.56x45mm loads. They are less forgiving with varied ammunition compared to standard or heavy bolt carrier groups, making them unsuitable for general-purpose or hard-use rifles where reliability across diverse conditions is critical. Shooters must balance the advantages of reduced recoil against the need for precise gas system adjustments, ensuring the rifle is optimized for the intended application.

Errors from a BCG

A subpar BCG can cause a range of malfunctions, compromising the rifle’s reliability and safety. Common errors include:

- Failure to Extract: Weak or worn extractor springs fail to grip spent casings, leaving them in the chamber, often seen with fouling-heavy calibers like 7.62x39mm.

- Failure to Eject: Inadequate ejector spring tension or a poorly staked gas key results in spent casings remaining in the action, causing double feeds.

- Misfires: A firing pin with insufficient protrusion or a loose retaining pin fails to ignite primers, particularly in hard-primer ammunition like surplus 7.62x39mm.

- Short-Stroking: Loose or improperly staked gas keys allow gas leaks, reducing cycling force, especially in under-gassed systems.

- Bolt Lug Fractures: Substandard bolt materials or lack of High-Pressure Testing (HPT) and Magnetic Particle Inspection (MPI) lead to cracked lugs, risking catastrophic failure under high pressures.

These issues typically arise from poor materials, inadequate heat treatment, or skipped quality control, emphasizing the importance of selecting a reputable bolt carrier group to avoid operational failures.

Knight’s Armament Company Proprietary Features

From time to time as you research bolt carrier groups, you might stumble across words written about Knight’s Armament. The Knight’s Armament Company (KAC) BCG features proprietary rounded bolt lugs, a design optimized for their SR-15 and SR-25 rifles. Unlike the standard angular lugs found on Mil-Spec bolts, KAC’s rounded lugs reduce stress concentrations, enhancing durability under high-pressure or rapid-fire conditions. This proprietary geometry improves the bolt’s resistance to cracking, particularly in demanding environments like full-auto or suppressed setups. However, the unique lug design makes the KAC bolt carrier group incompatible with standard AR-15 barrel extensions, restricting its use to KAC rifles but offering superior longevity and reliability in those systems.

Adjustable Gas Bolt Carrier Groups

Adjustable gas BCGs, such as the Bootleg Inc. Four-Position Adjustable Carrier, allow shooters to regulate gas flow directly at the carrier, offering an alternative to adjustable gas blocks. The Bootleg carrier features a side dial with four settings—full gas, reduced gas, minimal gas, and no gas—adjusted using a flathead screwdriver. Shooters remove the bolt carrier group, turn the dial to the desired setting, and reinstall, typically testing at the range to find the optimal configuration. This adjustability reduces gas blowback in suppressed rifles, softens recoil for competitive shooting, and optimizes reliability with varied ammunition, such as subsonic .300 AAC Blackout or high-pressure 5.56x45mm loads.

The primary benefits of adjustable gas bolt carrier groups include mitigating over-gassing in short-barreled or suppressed rifles, improving shooter comfort, and extending component life by reducing stress on moving parts. They are particularly useful when an adjustable gas block is impractical, such as in rifles with fixed front sight bases. Bootleg Inc. is a leading manufacturer, with their adjustable carrier recognized for reliability when tuned correctly. SureFire does not produce adjustable gas bolt carrier groups or any bolt carrier groups, focusing instead on suppressors, lights, and accessories, with no BCGs in their product lineup.

LMT Enhanced BCG

The Lewis Machine & Tool (LMT) Enhanced Bolt Carrier Group is a premium option engineered for extreme reliability in demanding applications, such as full-auto fire, suppressed setups, and short-barreled rifles. The carrier features a modified cam path that extends dwell time, delaying bolt unlocking to reduce chamber pressures and ease extraction, thereby minimizing stress on the bolt in over-gassed systems. Additional gas ports, angled forward, optimize gas flow and direct excess away from the shooter, reducing blowback in suppressed configurations. Relief grooves on the carrier channel debris, ensuring function in dirty conditions, such as sand or mud.

The bolt, crafted from a proprietary steel alloy stronger than Carpenter 158, incorporates redesigned lugs that flex slightly under high loads, reducing the risk of fractures during rapid or sustained fire. The “lobster tail” extractor employs dual springs, providing robust case extraction and maintaining reliability even if one spring weakens, a critical feature for prolonged engagements. These enhancements make the LMT Enhanced BCG ideal for professional shooters, law enforcement, or high-volume enthusiasts who require unyielding performance. However, its higher cost may exceed the needs of casual shooters with standard 16-inch or 20-inch unsuppressed rifles, where a quality Mil-Spec bolt carrier group suffices.

Popular Brands and Models

Dirty Bird Guns & Ammo proudly offers BCGs from manufacturers renowned for quality and reliability, with our own Dirty Bird bolt carrier group leading the pack:

- Dirty Bird Guns & Ammo: The Dirty Bird Enhanced 5.56 BCG sets the standard for reliability and value, featuring a 9310 steel bolt, HPT/MPI testing, and a black nitride finish that ensures durability and low maintenance. Precision-engineered for 5.56x45mm NATO and compatible calibers, it delivers consistent performance in tactical, competitive, or recreational applications, making it the top choice for shooters seeking quality without compromise.

- Bravo Company Manufacturing (BCM): Features Carpenter 158 bolts, HPT/MPI testing, and phosphate or nitride finishes, trusted for tactical reliability and robust construction.

- Aero Precision: Offers 9310 or Carpenter 158 bolts with nitride finishes, balancing affordability and performance for custom builds.

- Daniel Defense: Provides premium Carpenter 158 bolts with enhanced coatings, favored by professionals for unmatched durability.

Installation and Maintenance Tips

Proper installation and maintenance are essential to maximize bolt carrier group performance. During installation, align the bolt carrier group in the upper receiver, ensuring the gas key engages the gas tube and the cam pin is seated correctly. For custom builds, verify headspacing with a gunsmith to ensure safety, as improper headspacing can lead to dangerous pressure spikes or extraction failures. Maintenance involves cleaning the bolt carrier group after each use with a solvent to remove carbon buildup, followed by lubrication with high-quality gun oil to reduce friction. Regularly inspect the extractor spring, firing pin, and bolt lugs for signs of wear, replacing damaged parts promptly to prevent malfunctions. For bolt carrier groups with specialized coatings like nickel boron or nitride, ensure cleaning methods are compatible to preserve the finish’s integrity.

Debunking Common Myths

Misconceptions about bolt carrier groups can mislead shooters:

- Full-Auto Bolt Carrier Groups Are Illegal: These are legal for semi-auto rifles and enhance reliability by providing additional mass for stable cycling.

- All Nitride Finishes Are Equal: Quality varies significantly; premium manufacturers ensure consistent hardness and durability, unlike budget options that may lack uniformity.

- High-Pressure Testing Damages Bolt Carrier Groups: HPT verifies the bolt’s strength under extreme pressures without compromising its longevity, ensuring reliability in real-world conditions.

Conclusion: Selecting the Ideal Bolt Carrier Group

The bolt carrier group is the AR-15’s linchpin, demanding meticulous selection to ensure reliability and performance across diverse applications—recreational, tactical, or competitive. By evaluating caliber compatibility, materials, gas systems, weight, and specialized options like lightweight, adjustable gas, shooters can tailor their choice to specific needs. The premium LMT Enhanced Bolt Carrier Group offers unmatched durability for extreme conditions, while avoiding subpar units prevents critical errors like extraction failures or misfires. Dirty Bird Guns & Ammo recommends our own Dirty Bird Enhanced 5.56 BCG as the top choice, alongside BCM, Aero Precision, Daniel Defense, PSA, and Bear Creek Arsenal for their proven quality. Proper installation, diligent maintenance, and an understanding of advanced features empower shooters to optimize their rifle’s performance. With this guide, Dirty Bird Guns & Ammo equips you to select a bolt carrier group that transforms your AR-15 into a dependable, high-performing tool ready for any challenge.