AR Parts and Accesories, Bolt carrier Groups

A Comprehensive Guide to AR-15 Bolt Carrier Coatings: Choosing the Best Steel and Finish

Table of Contents

The AR-15 Bolt Carrier Group (BCG) is a critical component of your rifle, responsible for its cycling and overall reliability. Often referred to as the “heart” of the AR-15, the BCG plays a pivotal role in ensuring smooth operation and consistent performance. With various steel types and coatings available, choosing the right combination is essential for achieving the durability, efficiency, and performance you need—whether for tactical use, competition, or casual range days.

Dirty Bird Industries offers an extensive selection of AR-15 Bolt Carrier Groups designed to meet diverse needs. Our inventory includes various high-quality finishes and materials, ensuring you can find the perfect BCG to optimize your rifle’s functionality and longevity.

Understanding the AR-15 Bolt Carrier Group (BCG)

The AR-15 Bolt Carrier Group (BCG) is one of the most vital components of your rifle, acting as the driving force behind its semi-automatic functionality. It is responsible for several critical processes, including chambering rounds, firing, extracting spent cartridges, and resetting the hammer for the next shot. With a properly functioning BCG, your AR-15 can operate effectively.

A typical BCG consists of several key components:

- Bolt: Engages the chambered round, allowing for proper firing and extraction.

- Carrier: Holds the bolt and moves back and forth during the firing cycle.

- Gas Key (Carrier Key): Plays a role in redirecting gas to cycle the action.

- Firing Pin: Strikes the primer to ignite the cartridge.

- Cam Pin: Ensures proper alignment of the bolt and carrier during operation.

When selecting an AR-15 BCG, it’s essential to consider compatibility with your upper receiver, especially if you’re using a complete AR-15 upper with a bolt carrier group. Ensuring proper fit and alignment prevents malfunctions and enhances reliability, making choosing a high-quality BCG tailored to your specific build crucial.

Types of Steel Used in AR-15 BCGs

The type of steel used in an AR-15 Bolt Carrier Group (BCG) significantly impacts its durability, reliability, and performance. Understanding the materials commonly used can help you select the best option for your needs, whether building from scratch or maintaining your rifle with AR-15 bolt carrier group rebuild kits for sale. Here’s a closer look at the most common steel types and their applications:

8620 Steel (Carrier)

- Features: This steel is widely used for the carrier portion of the BCG due to its excellent balance of durability, machinability, and cost-effectiveness.

- Best Use Cases: Ideal for general-purpose rifles used in range shooting or recreational activities. It provides consistent performance without breaking the bank.

Carpenter 158 Steel (Bolt)

- Features: Known for its military specifications, Carpenter 158 is the standard for mil-spec bolts. It offers exceptional strength, reliability, and wear resistance.

- Best Use Cases: Perfect for high-stress applications such as tactical and duty use. Trusted by professionals and enthusiasts seeking reliability under demanding conditions.

9310 Steel (Bolt)

- Features: This advanced alloy is increasingly popular for AR-15 bolts. It provides improved tensile strength and fatigue resistance compared to Carpenter 158 while being more cost-effective for manufacturers.

- Best Use Cases: A great choice for precision shooters or those looking for a durable bolt without the premium price tag.

Comparing Steel Types

- Durability: Carpenter 158 and 9310 lead in strength and wear resistance, making them ideal for high-performance builds.

- Cost-Effectiveness: 8620 steel offers a budget-friendly option for general use, while 9310 provides a mid-range balance between performance and price.

- Application: Carpenter 158 is the standard for mil-spec builds, while 9310 is a modern alternative for those prioritizing innovation.

Compatibility Considerations

When selecting a steel type for your AR-15 BCG, ensure compatibility with your rifle’s setup and intended use. For those maintaining or upgrading their rifles, AR-15 bolt carrier group rebuild kits for sale can offer pre-matched components to ensure seamless integration. By selecting the right steel type, you can optimize your BCG for durability, reliability, and performance tailored to your needs.

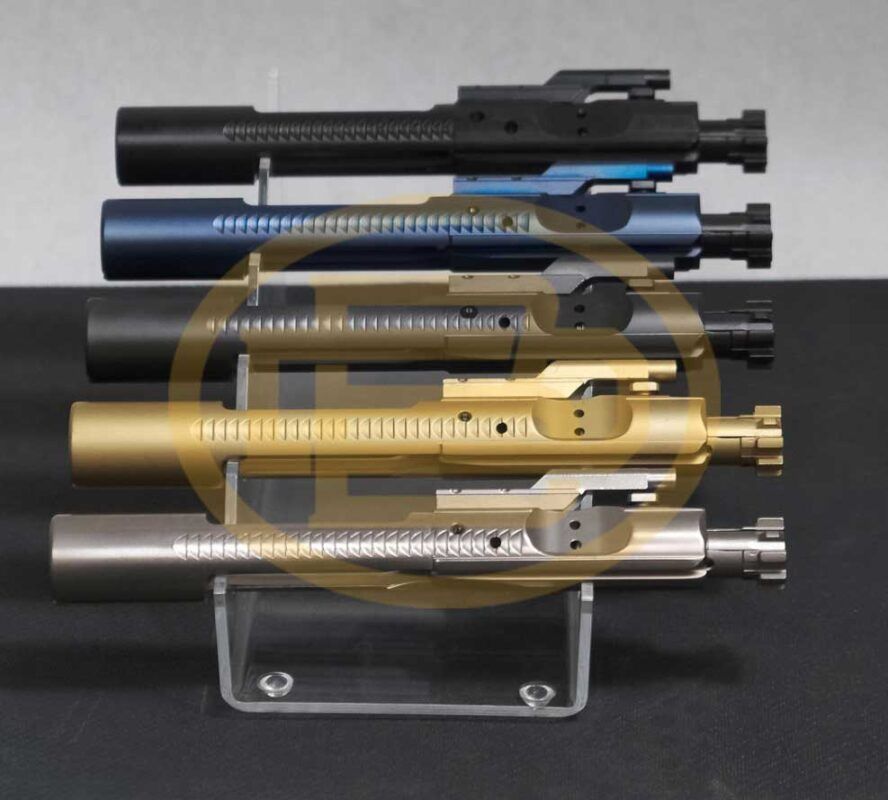

Popular Coating Finishes for AR-15 BCGs

Choosing the right coating for your AR-15 Bolt Carrier Group (BCG) is as important as selecting the correct steel. Coating finishes influence the BCG’s durability, ease of maintenance, and overall performance. Here’s a breakdown of the most popular coating options, their features, and ideal use cases.

Phosphate Finish

- Features: Known for its durability and ruggedness, the phosphate finish has a textured matte appearance and is highly affordable.

- Ideal For: This finish is best suited for rifles intended for rugged use and harsh conditions, where wear and tear are inevitable.

- Product Options: Explore the extensive range of phosphate-finished BCGs available on the Dirty Bird Industries.

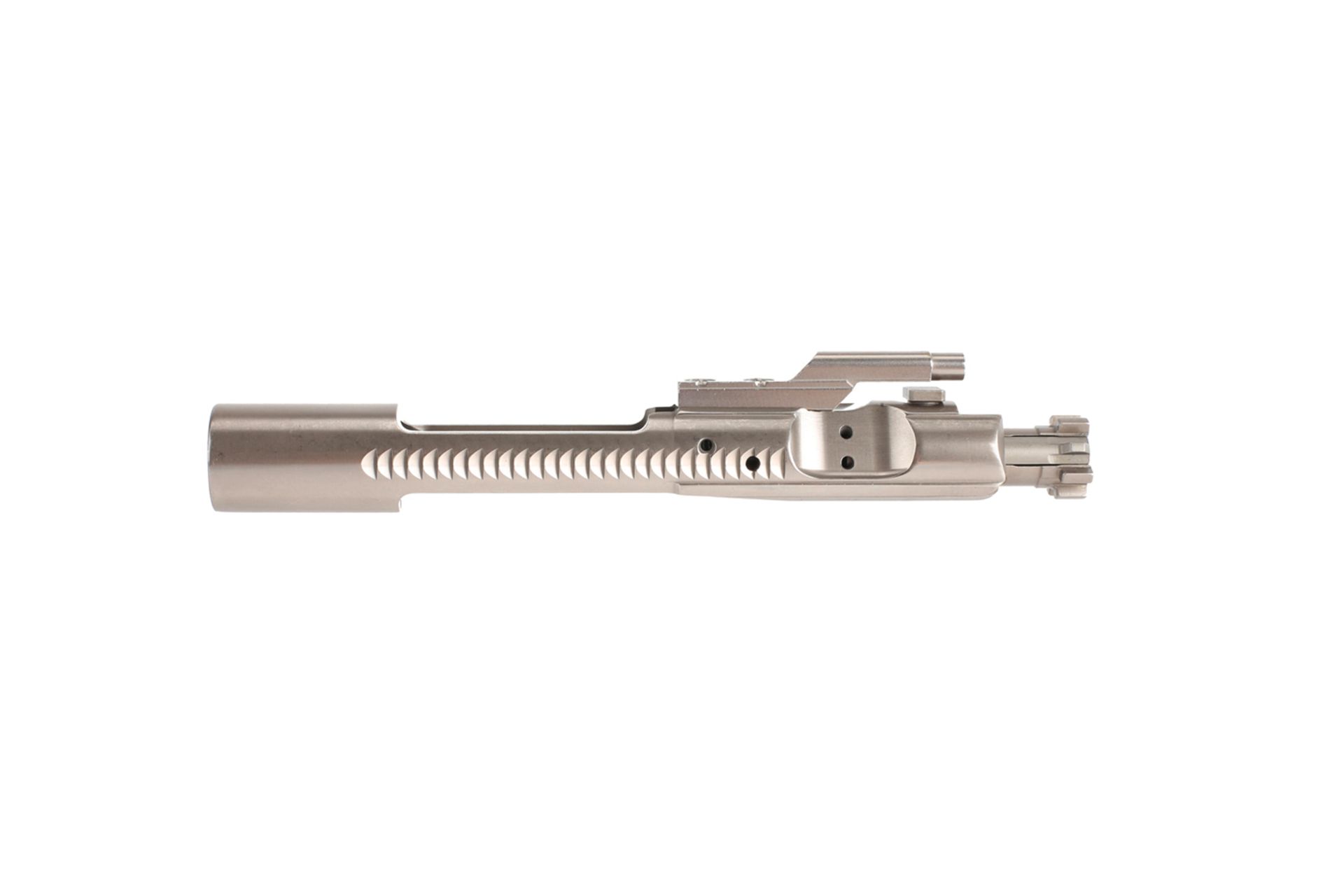

Nickel Boron (NiB)

- Features: NiB offers a slick surface that reduces friction, making the BCG easier to clean and more resistant to corrosion. Its shiny finish also adds a touch of style to your rifle.

- Ideal For: Designed for competitive shooters or those seeking smoother cycling and easier maintenance.

- Product Options: Check out Dirty Bird Industries’ selection of NiB-coated BCGs for a balance of performance and aesthetics.

Nitride (QPQ)

- Features: This finish boasts impressive hardness, wear resistance, and a sleek, smooth appearance. Nitride is highly durable and offers a balanced option for performance and affordability.

- Ideal For: Great for general-purpose AR-15 builds, combining cost-effectiveness with reliability.

- Product Options: Dirty Bird Industries carries several nitride-coated BCGs tailored to versatile builds.

Chrome Finish

- Features: Chrome coatings are known for their exceptional wear resistance and ease of cleaning. This finish has been a classic choice for decades due to its longevity and reliability.

- Ideal For: Suitable for rifles that endure heavy use or require high durability in extreme environments.

- Product Options: Browse chrome-finished BCGs on the Dirty Bird USA website for a classic yet dependable option.

By understanding the features and benefits of each coating, you can select a finish that aligns with your rifle’s purpose and maintenance preferences. Dirty Bird Industries offers various BCGs in these popular finishes, ensuring you find the perfect match for your AR-15 build.

Skeletonized AR-15 Bolt Carrier Groups: Benefits and Drawbacks

Skeletonized AR-15 Bolt Carrier Groups (BCGs) are designed for shooters seeking a lightweight and responsive firearm. While they excel in specific applications, it’s essential to consider their benefits and potential limitations to ensure they align with your rifle’s intended use.

Benefits of Skeletonized BCGs

- Lightweight Design:

The reduced material significantly lowers the overall weight of the rifle, making it ideal for competitive shooting where agility and maneuverability are key. - Faster Cycling Speeds:

The lighter weight can improve cycling speed, offering a performance boost in rapid-fire scenarios. - Unique Appearance:

Skeletonized BCGs often feature a modern, sleek aesthetic that can enhance the visual appeal of your build.

Drawbacks of Skeletonized BCGs

- Reduced Durability:

The removal of material may compromise structural strength, making these BCGs less suited for heavy-duty or high-stress applications. - Limited Heat Dissipation:

The reduced mass may affect heat dissipation during prolonged use, potentially impacting reliability in sustained shooting. - Fine-Tuning Required:

Lightweight BCGs may necessitate adjustments to the rifle’s gas system and buffer setup to maintain optimal performance.

By understanding the strengths and limitations of skeletonized BCGs, you can decide whether they are the right fit for your AR-15. These components are particularly advantageous for lightweight builds and competitive shooting, offering a combination of speed, style, and functionality. However, their application in demanding environments should be carefully evaluated to ensure they meet your expectations.

Maintenance and Cleaning of AR-15 BCGs

Proper maintenance of your AR-15 Bolt Carrier Group (BCG) is essential for ensuring reliable performance and extending the lifespan of your rifle. Refrain from regular cleaning and inspection to avoidmalfunctions and reduced efficiency, especially in high-use scenarios. Here’s a comprehensive guide to maintaining and cleaning your BCG effectively.

Why Regular Maintenance Matters

- Performance: Regular cleaning prevents carbon buildup, ensuring smooth cycling and consistent reliability.

- Longevity: Proper maintenance minimizes wear and tear, prolonging the life of the BCG and its components.

- Safety: A clean and well-lubricated BCG reduces the risk of malfunctions that could compromise safe operation.

Recommended Tools and Products

- AR-15 Bolt Carrier Group Cleaning Tool: Specifically designed to scrape carbon deposits from hard-to-reach areas like the bolt tail and carrier.

- Lubrication Products: High-quality gun oil or grease to ensure smooth operation and protect against corrosion.

- Soft Brush or Cloth: For wiping down surfaces and gently cleaning delicate areas.

- Cleaning Solvent: Helps break down stubborn carbon and grime.

Step-by-Step Guide to Cleaning and Inspecting the BCG

- Disassembly:

- Remove the BCG from the rifle and disassemble it into its components (bolt, carrier, firing pin, cam pin, and gas key).

- Cleaning the Components:

- Bolt: Use the cleaning tool to scrape away carbon deposits on the bolt tail and lugs. Apply solvent as needed for tough buildup.

- Carrier: Wipe down the carrier to remove residue, paying attention to the inside where the bolt sits.

- Gas Key: Use a small brush to clean inside the gas key, ensuring there are no obstructions.

- Firing Pin: Clean the firing pin with a soft cloth or brush, ensuring it’s free of grime.

- Inspection:

- Check for cracks, excessive wear, or other signs of damage on all components. Pay close attention to the gas key screws and bolt lugs for integrity.

- Lubrication:

- Apply a thin layer of gun oil to all moving parts, including the bolt, carrier, and firing pin. Focus on areas with friction points to ensure smooth cycling.

- Reassembly:

- Reassemble the BCG, ensuring all parts are correctly aligned and securely fastened.

- Final Check:

- Manually cycle the BCG to ensure it moves freely and smoothly before reinserting it into the rifle.

Following these steps and maintaining a consistent cleaning schedule can keep your AR-15 Bolt Carrier Group in top condition. Regular maintenance not only enhances performance but also ensures the reliability and safety of your rifle for years to come.

Choosing the Right BCG for Your Needs

Selecting the ideal AR-15 Bolt Carrier Group (BCG) involves balancing steel type, coating finish, and intended use. The right combination ensures your rifle operates reliably and efficiently in specific shooting scenarios.

Matching Steel and Coating Choices to Intended Use

- Home Defense:

- Opt for a BCG with a durable steel, such as Carpenter 158 or 9310, paired with a corrosion-resistant coating like Nickel Boron or Nitride. These options ensure reliability and smooth operation in high-stress situations.

- Competitive Shooting:

- A lightweight, skeletonized BCG made from 9310 steel with a slick coating like Nickel Boron or Chrome enhances cycling speed and reduces wear during rapid firing.

- Hunting:

- For outdoor environments, choose a BCG with a phosphate or Nitride coating for durability and resistance to harsh conditions. Steel options like 8620 for the carrier and 9310 for the bolt provide a good balance of strength and longevity.

Ensuring Compatibility

- AR-15 Bolt Carrier Group and Charging Handle:

- When selecting a BCG, ensure it is compatible with your upper receiver and charging handle. Proper fitment is crucial to prevent malfunctions and to maintain smooth cycling.

- Pay attention to the gas system length and any specific requirements of your rifle setup to ensure the BCG functions optimally.

By carefully considering your shooting needs and ensuring compatibility with your rifle’s components, you can select a BCG that maximizes performance, reliability, and efficiency in any scenario.

Frequently Asked Questions About AR-15 Bolt Carrier Groups

1. What is an AR-15 Bolt Carrier Group (BCG)?

The AR-15 Bolt Carrier Group (BCG) is a crucial rifle component responsible for cycling its action. It includes parts like the bolt, carrier, gas key, firing pin, and cam pin. Together, these components chamber rounds, extract spent casings and reset the rifle for the next shot.

2. What are the best materials for an AR-15 BCG?

The best material depends on your intended use:

- 8620 Steel: Commonly used for carriers, offering durability and cost-effectiveness.

- Carpenter 158 Steel: A mil-spec standard for bolts, known for its reliability.

- 9310 Steel: Provides higher strength and fatigue resistance, ideal for precision builds.

3. What are the most popular coatings for AR-15 BCGs?

Popular coatings include:

- Phosphate: Durable and affordable, great for rugged use.

- Nickel Boron (NiB): Corrosion-resistant and slick, ideal for smoother cycling and easy cleaning.

- Nitride (QPQ): Durable with a sleek finish, balancing affordability and performance.

- Chrome: Highly resistant to wear and easy to clean, suited for heavy use.

4. What is a skeletonized AR-15 Bolt Carrier Group?

A skeletonized BCG is a lightweight version of the traditional BCG. It features material cutouts to reduce weight, making it ideal for competitive shooting. However, it may sacrifice some durability and heat dissipation compared to standard designs.

5. How do I maintain and clean my AR-15 BCG?

To maintain and clean your BCG:

- Disassemble the BCG into its components.

- Use a cleaning tool to remove carbon buildup from the bolt and carrier.

- Wipe down all parts with solvent and lubricate moving areas.

- Inspect for wear or damage.

- Reassemble and test for smooth operation.

6. How do I choose the right BCG for my AR-15?

To choose the right BCG:

- Match the steel type (e.g., Carpenter 158 or 9310) and coating (e.g., NiB or Nitride) to your intended use, such as home defense, competition, or hunting.

- Ensure compatibility with your upper receiver and charging handle.

- Consider additional factors like weight (skeletonized vs. standard) and durability requirements.

7. Are skeletonized BCGs worth it?

Skeletonized BCGs are worth considering if you prioritize weight reduction and faster cycling, such as for competitive shooting. However, they may not be ideal for heavy-duty or high-stress applications due to potential durability trade-offs.

8. How often should I clean my AR-15 BCG?

For optimal performance, you should clean your BCG after each use or at least every 500-1,000 rounds. Frequent maintenance is essential if you shoot in dirty or harsh environments.

9. Can I replace individual parts of my BCG?

Individual parts like the bolt, gas key, or firing pin can be replaced. Rebuild kits allow you to maintain and repair your BCG without purchasing a new one.

10. Do all AR-15 BCGs work with any AR-15?

Not all BCGs are universally compatible. Ensure the BCG matches your upper receiver and gas system (e.g., carbine, mid-length, rifle). For specific setups, like piston systems, ensure compatibility with your rifle’s design.

Final Thoughts: Choosing the Perfect AR-15 Bolt Carrier Group

Selecting the proper steel and coating for your AR-15 Bolt Carrier Group is essential for achieving the performance, reliability, and durability you need. Whether you’re prioritizing ruggedness, corrosion resistance, or weight reduction, understanding the options available allows you to customize your rifle to match your specific shooting requirements.

Dirty Bird USA offers a versatile selection of high-quality BCGs featuring various materials and finishes to suit every shooter’s needs. From phosphate-coated options for rugged use to lightweight skeletonized designs for competitive shooting, you’ll find a solution tailored to your build.

Ready to upgrade your AR-15? Visit Dirty Bird USA today to explore our extensive collection of Bolt Carrier Groups and accessories. Equip your rifle with top-tier components and experience the difference in performance and reliability.

Additional Resources: Buying, Building and Training Tips For AR-Platform weapons