AR Parts and Accesories, AR-15, Bolt carrier Groups

AR-15 Bolt Carrier Groups Explained: Key Functions and Design

AR-15 Bolt Carrier Groups Explained Table of Contents

The AR-15 Bolt Carrier Group (BCG) is the heart of your firearm’s operation, playing a vital role in the cycling process that makes semi-automatic fire possible. This critical assembly contains essential components like the bolt, cam pins, firing pin, and gas key, each working reliably in unison to chamber, fire, extract, and eject rounds. Regarding AR-15 performance, a well-maintained BCG can mean the difference between smooth operation and frustrating malfunctions.

Bolt Carrier Groups are not just about functionality; they influence accuracy, reliability, and even the lifespan of your firearm. Key components such as bolt assemblies ensure precise alignment during firing, while extractor and ejector springs help maintain reliable feeding and expulsion of spent casings. Gas rings and gas keys direct gas flow to cycle the action, while the firing pin’s precision ensures consistent ignition.

Whether you’re a seasoned AR-15 owner or just learning the intricacies of this platform, understanding the AR-15 bolt carrier group and its components is essential. From standard to enhanced and lightweight designs, selecting and maintaining the right BCG can enhance your shooting experience and improve your firearm’s reliability in any condition. Dive into the details to unlock the full potential of your AR-15.

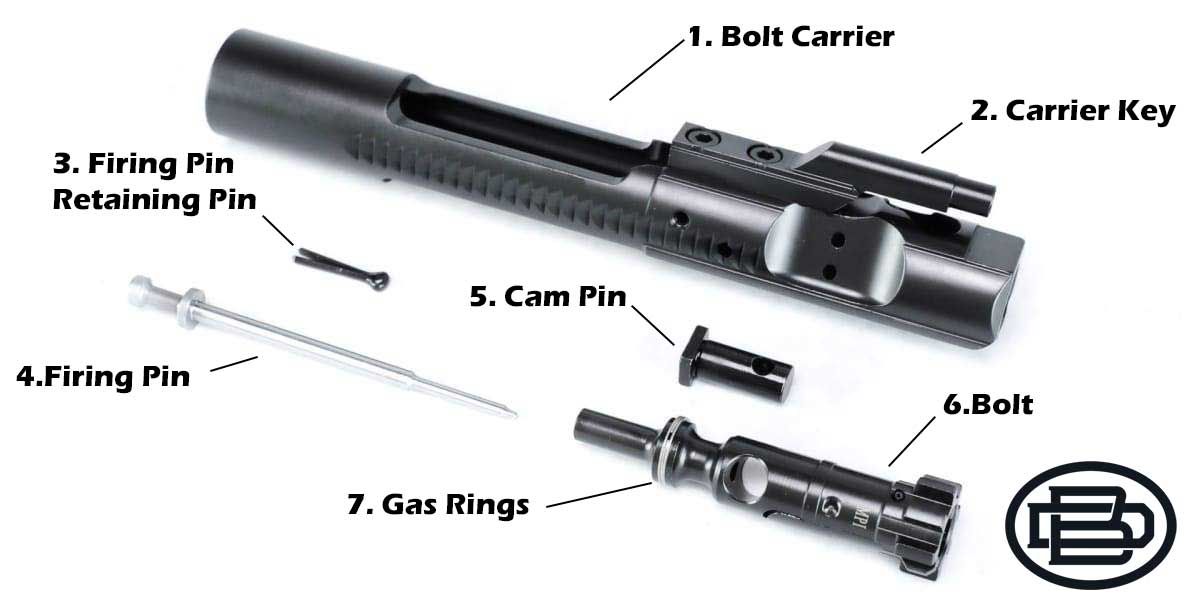

Components of an AR-15 Bolt Carrier Group (BCG)

AR-15 Bolt Carrier Groups (BCG) comprise critical components essential for cycling, reliability, and performance. Each piece plays a crucial role in smooth firearm operation.

Bolt Carrier

Description: The bolt carrier houses and supports the bolt, enabling the essential cycling operations of the AR-15.

Importance: By moving to chamber new rounds, eject spent casings, and reset the firing mechanism, the bolt carrier ensures reliable semi-automatic function. Additionally, it plays a key role in the overall stability and smoothness of the firearm’s action.

Carrier Key

Description: The carrier key is mounted to the top of the bolt carrier and channels gas from the gas tube into the carrier to drive the action.

Importance: This component is crucial for directing gas pressure that propels the cycling action, enabling both semi-automatic and automatic fire. Proper carrier key staking prevents gas leaks, maintaining efficient cycling.

Firing Pin Retaining Pin

Description: This pin secures the firing pin within the bolt carrier, preventing unwanted movement that could lead to malfunctions.

Importance: Ensuring that the firing pin is correctly positioned is critical for consistent, reliable primer strikes. It also minimizes the risk of damage or jamming during operation.

Firing Pin

Description: The firing pin strikes the primer of a cartridge, igniting the propellant and firing the round.

Importance: For consistent and reliable ignition, the firing pin must be precisely manufactured and durable. Any deformation or wear can lead to misfires.

Cam Pin

Description: The cam pin facilitates the rotation of the bolt, locking and unlocking it with the barrel extension.

Importance: This rotation ensures the bolt locks securely during firing and unlocks smoothly for extracting spent casings. Proper function is vital for safe and reliable operation.

Bolt Assembly

Description: The bolt assembly houses the firing pin and engages with the cartridge for chambering, firing, and extraction.

Importance: This assembly provides alignment, proper locking with the barrel extension, and secure chambering, ensuring safe, accurate, and consistent firing.

Gas Rings

Description: The gas rings create a seal around the bolt, retaining gas pressure within the bolt carrier.

Importance: By preventing gas from escaping, the gas rings maintain sufficient pressure for reliable cycling of the action, enhancing performance and consistency.

Extractor

Description: Located within the bolt, the extractor grips the cartridge’s rim to remove it from the chamber.

Importance: The extractor ensures reliable removal of spent casings, a crucial step for smooth cycling and preventing jams.

Ejector

Description: This spring-loaded component, found in the bolt face, ejects spent cartridges after extraction.

Importance: Reliable and consistent ejection is necessary to prevent jams and maintain smooth, uninterrupted cycling of rounds.

Ejector Spring

Description: Provides the tension needed for the ejector to push spent casings out of the firearm.

Importance: This tension ensures consistent ejection, minimizing the risk of malfunctions and improving overall cycling reliability.

Extractor Spring

Description: Supplies tension to the extractor, ensuring it grips the cartridge case rim securely.

Importance: Proper tension is critical for securely extracting spent casings, enabling smooth operation during cycling.

Bolt Lugs

Description: These locking lugs on the bolt engage with the barrel extension to lock the bolt.

Importance: Secure locking is vital for containing high-pressure gases during firing, ensuring the safety and structural integrity of the firearm. Proper engagement reduces wear and enhances reliability over time.

Functions of the Bolt Carrier Group

Cycle Operation

The AR-15 Bolt Carrier Group (BCG) is central to the cycling action of the AR-15, allowing it to function as a semi-automatic firearm. When a round is fired, expanding gases from the ignited cartridge are directed through the gas tube and into the gas key on the BCG. This gas pressure propels the bolt carrier rearward, extracting and ejecting the spent casing from the chamber. As the AR-15 Bolt Carrier Group moves back, it compresses the buffer spring and resets the hammer, preparing for the next shot. The buffer spring then pushes the BCG forward, stripping a new round from the magazine and chambering it, readying the firearm for the next trigger pull. This automatic cycling allows rapid follow-up shots with minimal manual effort, enhancing the AR-15’s reliability and performance.

Locking Mechanism

The bolt must lock securely into the barrel extension to safely manage the immense pressure generated when firing a cartridge. The cam pin within the BCG facilitates this process by rotating the bolt into a locked position as it moves forward, engaging the lugs on the barrel extension. This locking mechanism ensures that the high pressures from the ignited fuel are safely contained within the chamber, protecting the shooter and preserving the structural integrity of the firearm. As the gas pressure decreases, the bolt unlocks and continues cycling, extracting the spent casing and chambering the next round to maintain reliable operation.

Ejection

The AR-15 Bolt Carrier Group also plays a crucial role in the ejection of spent cartridges. As the bolt moves rearward after firing, the extractor pulls the spent casing from the chamber while the ejector pushes it out through the ejection port. This ejection process is essential for maintaining consistent cycling and preventing jams. A properly functioning ejector spring and extractor ensure smooth, reliable removal of spent cases, contributing to the firearm’s overall dependability and performance. Regular inspection of these components helps prevent malfunctions. This seamless extraction and ejection process enables consistent, trouble-free operation of the AR-15, ensuring readiness and reliability during shooting sessions.

Types of Bolt Carrier Groups

The (BCG) has various configurations designed to meet different needs and preferences. From standard mil-spec BCGs offering trusted reliability to enhanced versions for greater durability and smoother operation and lightweight models prioritizing speed and agility, choosing the right BCG is crucial for optimal performance. Selecting the best option depends on your intended use and shooting style.

Standard BCG

A standard AR-15 Bolt Carrier Group follows the traditional military specification (mil-spec) design and is known for its proven reliability, durability, and compatibility with most AR-15 builds. These BCGs are typically made from high-strength materials, such as 8620 steel for the carrier and Carpenter 158 steel for the bolt. The components are treated with phosphate or nitride coatings to resist corrosion and wear. The mil-spec configuration ensures smooth, reliable cycling and dependable function across various AR-15 platforms, making it an excellent choice for general-purpose shooting, home defense, and training. Many users, from beginners to experienced shooters, appreciate the consistency and versatility of standard BCGs.

Enhanced BCG

Enhanced AR-15 Bolt Carrier Groups incorporate design upgrades and improved materials to provide superior performance, longevity, and smoother cycling compared to standard options. These BCGs often have specialized coatings, such as nickel-boron, nitride, or chrome, which reduce friction, enhance corrosion resistance, and simplify cleaning. Enhanced designs may feature optimized gas key staking, upgraded cam pins, and strengthened extractor springs for reliable extraction and ejection. These modifications improve cycling, reduced wear, and better function in adverse conditions. Enhanced BCGs are popular among shooters who demand exceptional performance for high-volume training, competitive shooting, or tactical applications.

Lightweight BCG

Lightweight AR-15 Bolt Carrier Groups are specifically engineered to minimize overall weight, resulting in faster cycling speeds and reduced felt recoil. This enables quicker follow-up shots and enhanced handling, which is especially useful in high-speed competition scenarios. L lightweight BCGs are typically constructed from materials like titanium or aluminum and treated with advanced coatings to maintain reliability while reducing mass. However, reducing weight can impact recoil dynamics and may require tuning the buffer system or gas block for optimal function. Lightweight BCGs are best suited for shooters seeking improved speed and agility without sacrificing dependability when properly configured.

Maintenance Tips for Bolt Carrier Groups

Maintaining your AR-15 Bolt Carrier Group (BCG) is essential for reliable performance, safety, and extending the lifespan of your firearm. The BCG is a crucial component that experiences heavy use and can quickly accumulate carbon buildup and fouling during shooting sessions. If not addressed, this buildup can lead to malfunctions such as jams, misfires, sluggish cycling, and accelerated wear of critical parts. Regular cleaning and proper lubrication keep friction low, protect metal surfaces, and ensure smooth operation of your AR-15.

To begin maintenance, first disassemble the BCG. Carefully remove and separate components like the bolt, firing pin, cam pin, and extractor. Thoroughly clean each part, paying particular attention to areas prone to carbon buildup. For example, the bolt head often collects heavy carbon deposits. Use a carbon scraper, cleaning brush, or solvent to remove these deposits effectively. Similarly, clean the firing pin to ensure no residue remains, as any buildup here can cause light primer strikes. Clean inside the carrier and around the gas rings to prevent friction or cycling issues.

The gas key is another critical area. Make sure it’s free of obstructions and inspect it to ensure it is properly staked (screws should be tightly fastened and peened over) to prevent gas leaks, which could disrupt cycling. For example, if you notice a loose gas key, you may experience gas flow issues, leading to poor performance. Next, check the extractor spring for tension and any signs of wear—worn springs can lead to unreliable case extraction, causing jams. Replace springs if they appear weak or damaged.

After cleaning, apply a thin coat of lubricant to moving parts, including the bolt, cam pin, rails, and inside the carrier. For example, a light coating of gun oil on these parts reduces friction during firing and ensures smoother cycling. Be careful not to over-lubricate, as too much oil can attract dirt and debris, causing further issues.

Generally, clean your AR-15 Bolt Carrier Group after firing 200-300 rounds or more frequently during extended shooting sessions, or if exposed to dirt, moisture, or harsh conditions. Regular maintenance ensures consistent performance and extends the life of your firearm’s critical parts. Keeping your BCG clean and lubricated will help guarantee that your AR-15 operates smoothly and is ready when needed.

Conclusion

AR-15 Bolt Carrier Groups (BCG) are the essential engine driving the reliable operation of your AR-15. From chambering and firing rounds to extracting and ejecting spent casings, the BCG directly impacts your firearm’s performance, accuracy, and safety. Understanding how each component—like the bolt, cam pins, extractor, and gas keys—contributes to this process is critical for any AR-15 enthusiast or professional.

To maintain optimal function, regular inspection and maintenance of your BCG are crucial. Cleaning away carbon buildup, properly lubricating moving parts, and checking components like extractor springs and gas keys help prevent malfunctions, such as misfires or feeding issues. Consistent upkeep not only extends the lifespan of your BCG but also keeps your AR-15 operating at peak reliability.

For those looking to upgrade, enhanced or lightweight BCGs can deliver smoother cycling, better durability, or reduced recoil. Tailoring your BCG to fit your specific needs boosts overall performance, giving you the edge on the range or in critical situations.

Consider purchasing your next AR-15 bolt carrier group or upgraded components from Dirty Bird Industries to ensure the best quality and reliability. Their selection and expertise can help you maximize your AR-15’s potential.

Additional Resources: News and Reviews Regarding AR Platform

Don’t use a carbon scraper on the bolt head .

We stopped doing that years ago .

By doing that you can adversely affect wear on the bolt head