Bolt carrier Groups

Understanding the M16 Bolt Carrier Group: The Heart of Your AR-15

Table of Contents

The bolt carrier group (BCG) is a cornerstone of any AR-15 or M16-pattern rifle, sparking endless discussions among firearms enthusiasts. For shooters, builders, and collectors shopping at Dirty Bird Guns & Ammo, grasping the BCG’s role, its variations, and the importance of quality is key to crafting a reliable, high-performing rifle. This guide dives into the differences between AR-15 and M16 BCGs, explains why quality is non-negotiable, and covers maintenance, coatings, and practical advice to help you select the ideal BCG for your build.

Clearing the Confusion: AR-15 vs. M16 Bolt Carrier Groups

Few topics in the AR community generate as much confusion as the distinction between AR-15 and M16 bolt carrier groups. Misinformation, outdated myths, and loose terminology often muddle the conversation. The following breakdown sets the record straight.

Historical Roots and Design Purpose

The AR-15, launched by Colt in the 1960s as a civilian semi-automatic rifle, shares its lineage with the M16, which the U.S. military adopted in 1964 for selective-fire capabilities, including semi-automatic and full-automatic or burst modes. The M16 BCG was engineered to withstand the demands of full-auto fire, cycling at high rates and enduring intense heat, pressure, and debris. In contrast, the AR-15 BCG was designed for semi-automatic civilian use, optimized for simplicity and lighter weight, omitting features unnecessary for single-shot operation. That difference in intended use shapes each carrier’s design: the M16 BCG is built for durability under extreme conditions, while the AR-15 BCG is tailored for lighter, less demanding applications.

Key Structural Differences

The primary distinction between the two carriers is the full-auto lug, a protruding shelf at the rear of the M16 carrier. That lug engages the auto sear in true full-auto lowers, enabling correct timing for full-auto or burst fire. AR-15 carriers lack this lug, which makes them lighter and incompatible with full-auto functionality. Typical weights are roughly 10 to 11 ounces for AR-15 carriers and 11 to 12 ounces for M16 carriers, though exact numbers vary by manufacturer and finish. The M16 carrier often has additional steel mass at the tail, which increases momentum and helps ensure reliable cycling in dirty, hot, or suppressed conditions.

A persistent myth is that installing an M16 BCG in a civilian AR-15 makes the rifle capable of full-auto fire. That is incorrect. Full-auto operation requires a registered machine gun lower with the appropriate sear mechanism, regulated under the National Firearms Act. Markings like “M16” on surplus carriers often indicate military origin but do not change legal status, and M16-style BCGs are common and legal in civilian builds.

Compatibility in Modern Builds

M16 BCGs are interchangeable with AR-15 uppers and lowers, which gives builders flexibility. The added mass of an M16 carrier can smooth reciprocation, particularly in carbine-length gas systems such as those on 14.5-inch M4-style barrels, and can improve feeding and reliability in suppressed setups where backpressure changes the timing. Many shooters report more consistent ejection patterns with the heavier carrier, such as consistent 3 o’clock ejections versus occasional weaker 4:30 ejections with lighter carriers. For pure semi-auto use, the difference is subtle, but the M16 carrier’s robustness makes it a preferred choice for duty, tactical, and suppressed rifles. For competition builds where every ounce matters, a lighter AR-15 carrier may be preferred.

Choosing the Right BCG for Your Needs

For most applications the M16-style BCG is the preferred choice because of its robustness and adaptability. The added weight helps minimize bolt bounce, which can improve accuracy during rapid fire, and its construction tends to perform better in hot, dirty, or suppressed environments. AR-15 BCGs are lighter and can benefit builds where reduced reciprocating mass is a priority.

Consider your rifle’s purpose. Tactical and duty rifles benefit from the M16-style carrier’s durability, while lightweight competition setups may favor a lighter AR-15 carrier. Availability and price are also factors, as M16-style BCGs are widely produced and often easy to source from reputable brands at Dirty Bird Guns & Ammo.

The Bolt Carrier Group: How It Works and Why It Matters

The BCG is the dynamic engine of the AR-15’s firing cycle. In milliseconds it chambers a round, locks the bolt, fires the round, unlocks after firing, extracts the spent casing, ejects it, and returns to battery for the next shot. Gas redirected from the barrel drives this process. In semi-automatic firearms the system delivers precise single-shot performance, and in M16 derivatives the carrier supports high-rate full-auto or burst fire.

Because the BCG manages that entire sequence, failures in the BCG such as cracked bolts, a loose gas key, or a worn cam pin can stop the rifle cold or produce dangerous malfunctions. Beyond preventing failures, a high-quality BCG improves ergonomics by reducing felt recoil and muzzle rise, enabling faster follow-up shots. Premium coatings and finishes also help the BCG run cleaner with less lubrication and reduce carbon buildup.

Why Quality Matters in a Bolt Carrier Group

Quality is critical for a component that endures extreme pressures and temperatures on every shot. Substandard materials or poor machining can lead to cracks, peening, or premature wear and can turn a dependable rifle into an unreliable one.

Mil-spec BCGs undergo shot peening, a process that bombards the bolt with steel spheres to induce compressive stresses and improve fatigue resistance. Many premium BCGs use advanced alloys such as 9310 or other proprietary steels that offer improvements over standard Carpenter 158 in hardness and ductility. These steels resist hydrogen embrittlement from certain cleaners and hold up better in suppressed or over-gassed setups.

Proper assembly details matter too. Gas keys should be staked to prevent gas leakage or loosening. Bolts that have passed magnetic particle inspection (MPI) and high-pressure testing (HPT) offer documented assurance of crack-free service under load. Firing pins with corrosion-resistant treatments and properly hardened cam pins extend service life. Cheap BCGs may fail after a few thousand rounds, while a well-made, properly maintained BCG can last tens of thousands of rounds, making the higher upfront cost a long-term value.

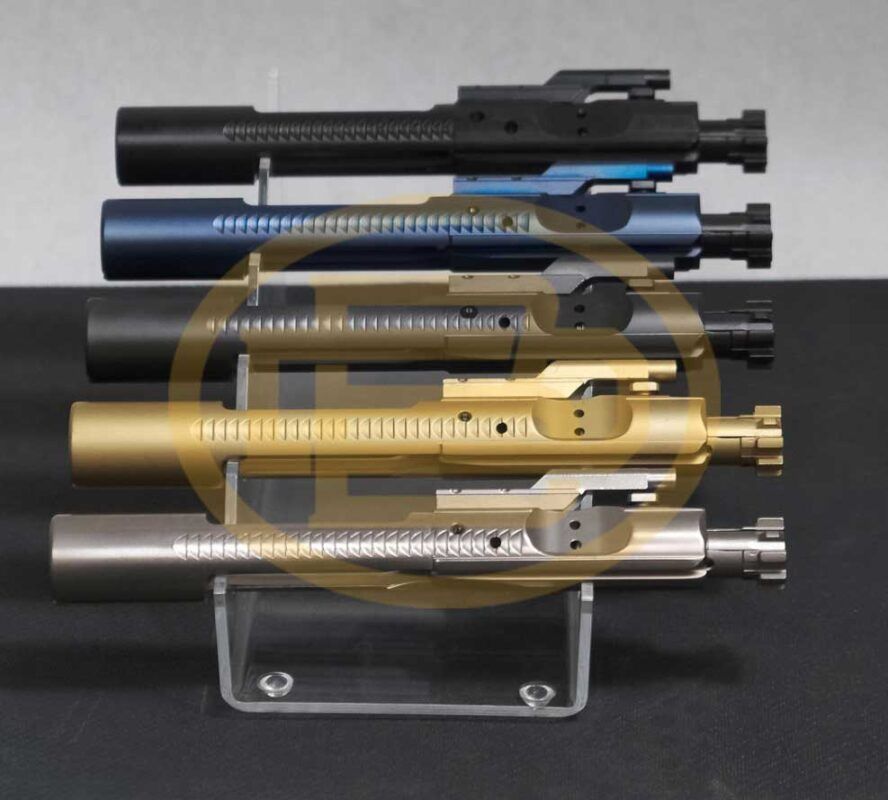

Coatings: Enhancing Durability and Performance

Coatings protect BCGs from wear and corrosion. Standard parkerizing, or manganese phosphate, is cost-effective and holds lubricant well but can scratch. Black nitride and salt-bath nitride offer superior corrosion resistance, surface hardness, and easier cleaning. Nickel boron provides a slick, easy-to-clean surface and can reduce the need for heavy lubrication. Diamond-like carbon coatings deliver excellent hardness and wear resistance but command a premium price.

For most shooters, the balance of durability, ease of maintenance, and value makes nitride-coated M16-style BCGs a practical recommendation.

Maintenance: Keeping Your BCG in Top Shape

Routine maintenance keeps any BCG performing reliably. Cleaning every 500 to 1,000 rounds is a good standard. That typically includes brushing carbon from the bolt face and lugs, soaking in solvent for stubborn deposits, inspecting gas key staking, and generously lubricating carrier rails. Avoid harsh chemical cleaners that can embrittle steel. With proper care, a premium BCG can last well beyond budget alternatives and prevent failures in the field.

Conclusion: Choose the Best Heart for Your Rifle

The bolt carrier group is the heart of your AR-15 platform. Investing in a well-made BCG pays dividends in reliability, safety, and long-term value. For most shooters, the M16-style BCG offers superior versatility and robustness, while the AR-15 carrier still has a place in lightweight competition builds.

If you are building or upgrading, prioritize certified materials, proper machining, and trusted coatings. Visit Dirty Bird Guns & Ammo to explore curated BCG selections and get expert guidance tailored to your rifle’s role. Your rifle’s heart deserves the best, so choose wisely.