AR Parts and Accesories, AR-15, Bolt carrier Groups

Common AR-15 Bolt Carrier Group (BCG) Issues and Their Fixes

Table of Contents

The Bolt Carrier Group (BCG) is one of the most critical components of the AR-15, responsible for cycling the firearm’s action. At Dirty Bird Guns & Ammo, we recognize the importance of a reliable BCG for firearm performance. While a high-quality BCG can deliver years of reliable service, even the best setups can encounter issues due to wear, maintenance, or external factors. This article dives into the major components of the BCG, common problems, and actionable solutions to keep your AR-15 running smoothly.

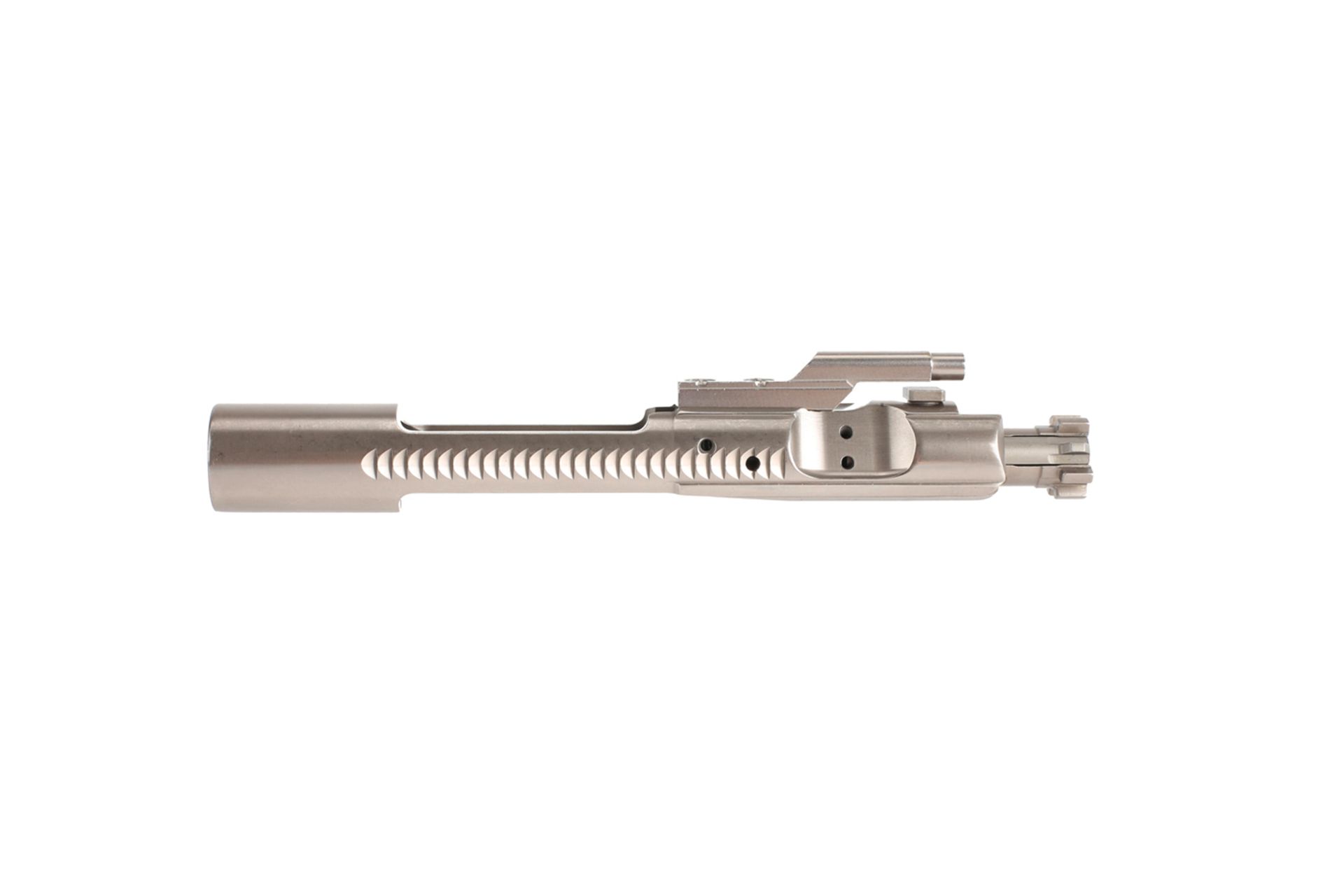

Understanding the Components of a BCG

The Bolt Carrier Group is composed of several key parts that work together to ensure the firearm operates correctly. At Dirty Bird Guns & Ammo, we emphasize the importance of understanding these components:

- Carrier: This is the external housing for the bolt and is attached to the gas key. Regular inspection and cleaning of the carrier are essential, as loose screws on the gas key can cause malfunctions.

- Bolt: The bolt guides the round into the chamber, extracts the spent case, and ejects it after firing. It’s a critical component but also a common point of failure due to the stress it endures.

- Gas Key: Also known as the bolt carrier key, it channels gas from the gas tube into the bolt carrier. It should be securely fastened and properly staked to prevent screws from loosening.

- Firing Pin: This strikes the cartridge primer, initiating the firing sequence. This component requires periodic cleaning to ensure reliability.

- Cam Pin: The cam pin secures the bolt within the carrier and facilitates its locking and unlocking action. Excessive wear on the cam pin can compromise the overall function of the firearm.

- Gas Rings: Gas rings are essential for maintaining a tight seal within the bolt carrier, ensuring the proper cycling of the firearm. Inspect gas rings regularly, and don’t worry about common myths like needing perfect alignment—they are designed to function regardless of alignment.

The BCG: A Component You Shouldn’t Skimp On

When building or upgrading an AR-15, it can be tempting to save money by choosing lower-cost components. However, the Bolt Carrier Group is not the place to cut corners. The BCG is the heart of the AR-15’s operating system, responsible for critical functions such as chambering, firing, extracting, and ejecting rounds. A failure in any of these areas can render your firearm unreliable, or worse, completely inoperable.

High-quality BCGs are manufactured with durable materials such as Carpenter 158 or 9310 steel and undergo rigorous testing, including Magnetic Particle Inspection (MPI) and High-Pressure Testing (HPT). These processes ensure the BCG can handle the stresses of repeated firing without premature wear or failure. Cheaper BCGs, on the other hand, often lack proper staking on the gas key, use lower-grade materials, or skip essential testing. These cost-cutting measures can lead to loose components, cracked bolt lugs, or inconsistent cycling.

Investing in a reliable Bolt Carrier Group is not just about performance; it’s about safety and peace of mind. At Dirty Bird Guns & Ammo, we recommend selecting a BCG that meets or exceeds Mil-Spec standards, ensuring your AR-15 operates smoothly and reliably in any situation.

Importance of a Properly Staked Gas Key

When we think of staking in the AR-15 platform, the first thing that often comes to mind is the castle nut at the rear of the receiver. While staking the castle nut is crucial to keep the buffer tube assembly secure, staking the gas key is just as important for the proper function of the Bolt Carrier Group.

The Bolt Carrier Group gas key directs gas into the bolt carrier to cycle the firearm, and if it is not securely fastened, it can loosen over time, causing malfunctions. Proper staking ensures the screws remain tight under the stress of repeated firing. At Dirty Bird Guns & Ammo, we recommend checking your gas key for secure staking as part of routine maintenance. If the screws appear loose or improperly staked, you may need to restake them or replace the carrier entirely.

Clear Signs Your Bolt Carrier Group is Causing Issues

The Bolt Carrier Group is a critical part of the AR-15’s operation, and problems with it can manifest in various ways. Here are some clear signs that your BCG may be the root cause of your firearm’s malfunctions:

- Failure to Extract or Eject: If you notice spent casings failing to eject or becoming stuck in the chamber, this can indicate a problem with the extractor or extractor spring. Weak or worn components in the bolt carrier group can lead to incomplete cycling.

- Misfeeds or Failure to Feed: If rounds are failing to load properly into the chamber, the issue may be with worn-out gas rings, insufficient gas pressure, or a damaged feed ramp. The BCG plays a significant role in ensuring smooth feeding.

- Bolt Not Locking Back: A bolt that fails to lock back after the last round often points to gas system issues or a weak buffer spring. The BCG may not be receiving enough gas pressure to complete the cycle.

- Unusual Wear Patterns: Inspect the bolt carrier group for excessive wear on components such as the cam pin, bolt lugs, or gas key. Premature or uneven wear can indicate improper lubrication or low-quality materials.

- Light Primer Strikes: If your rifle fails to fire consistently, light primer strikes caused by a fouled firing pin or weak hammer spring could be the culprit. These issues often originate from the BCG.

- Excessive Carbon Buildup: If your BCG shows heavy fouling despite regular cleaning, it may indicate an over-gassed system or poor-quality components that don’t handle heat and debris effectively.

- Loose Gas Key Screws: A gas key that has come loose can lead to inconsistent cycling or failure to properly chamber and fire rounds. This is why proper staking is essential.

- Abnormal Cycling: Slow or sluggish cycling, failure to fully chamber a round, or an overly harsh recoil impulse can all be signs of a problem with the BCG’s functionality or its interaction with the gas system.

If you notice any of these signs, it’s important to inspect your bolt carrier group closely and address any worn, damaged, or improperly functioning components. Regular maintenance and high-quality bolt carrier group replacement parts from Dirty Bird Guns & Ammo can prevent these issues and keep your firearm operating reliably.

Common BCG Issues and Their Fixes

Failure to Extract (FTE)

One frequent issue is the failure to extract (FTE). This problem often stems from a weak extractor spring, a worn extractor, or excessive fouling in the chamber. When the extractor cannot properly grip the spent casing, it fails to eject, leading to a malfunction. To fix this, inspect and replace the extractor spring, opting for an upgraded spring kit with an O-ring for improved tension. Regular cleaning of the extractor and chamber can also help prevent fouling from causing extraction issues.

Failure to Feed (FTF)

Another common problem is failure to feed (FTF). This can occur due to worn-out gas rings, underpowered ammunition, or a damaged feed ramp. When the bolt lacks the necessary pressure to cycle fully, it can cause the next round to misalign or jam. At Dirty Bird Guns & Ammo, we recommend inspecting gas rings for wear and replacing them if necessary. Using quality ammunition can also improve reliability, as low-powered rounds may not generate enough force to cycle the action. If the feed ramp is damaged, polishing or repairing it can ensure smooth feeding.

Bolt Failing to Lock Back

One frustrating issue AR-15 owners encounter is the bolt failing to lock back after the last round. This is typically caused by gas system issues, a weak buffer spring, or a misaligned gas block. A misaligned gas block restricts the flow of gas necessary for cycling, while a weak buffer spring can prevent the bolt from locking back properly. To resolve this, check the gas block alignment and ensure the gas tube is clear of obstructions. If the buffer spring is worn, replacing it with a new one can restore proper function.

Excessive Wear on the Bolt Carrier Group Cam Pin

Excessive wear on the cam pin is another issue that can lead to reliability problems. This often results from inadequate lubrication or low-quality materials. The cam pin experiences significant stress during operation, and without proper lubrication, it can wear prematurely. To prevent this, ensure the BCG is well-lubricated with a high-quality firearm lubricant. If the cam pin shows excessive wear, replacing it with a durable, heat-treated version is recommended.

Light Primer Strikes

Light primer strikes can be a significant problem, especially if they cause your rifle to fail to fire. This issue is usually due to a weak hammer spring, a fouled firing pin, or improper assembly of the BCG. Cleaning the firing pin and ensuring the BCG is properly assembled can often resolve this issue. If the hammer spring is weak, replacing it with a heavier-duty version can improve reliability.

Bolt Stuck in Battery

Sometimes, the bolt can become stuck in the battery, preventing it from cycling. This can be caused by an over-gassed system, a dirty chamber, or excessive carbon buildup on the bolt. Cleaning the chamber and bolt thoroughly can alleviate this issue. For rifles with an over-gassed system, installing an adjustable gas block allows you to fine-tune the gas flow and reduce the likelihood of this problem occurring.

Loose Gas Key

A loose gas key is another problem that can cause malfunctions in the AR-15. The gas key is responsible for directing gas into the carrier, and if its screws are not properly staked, it can loosen over time. At Dirty Bird Guns & Ammo, we recommend restaking the screws with the proper tools or replacing the carrier if the threads are stripped. Using a thread locker can also help ensure the screws stay secure.

Excessive Gas Blowback

Excessive gas blowback can be an issue for shooters using suppressors or dealing with an over-gassed system. Blowback can cause discomfort and even interfere with the rifle’s cycling. Installing an adjustable gas block is an effective solution, as it allows you to regulate the amount of gas entering the system. Additionally, suppressor-optimized charging handles can help mitigate blowback by directing gases away from the shooter’s face.

Cracked Bolt Lugs

Cracked bolt lugs in your bolt carrier group are a serious issue that can result from overuse, poor-quality steel, or out-of-spec headspace. The bolt lugs endure significant stress during firing, and any flaws can lead to cracks. Replacing the bolt with one made of high-quality materials, such as Carpenter 158 or 9310 steel, is crucial for long-term durability. Ensuring proper headspace with the new bolt is also essential to prevent further issues.

Cycling Problems Due to Lack of Lubrication

The Bolt Carrier Group can sometimes fail to move freely, causing cycling problems. This often happens due to insufficient lubrication, debris, or out-of-spec components. Cleaning the BCG and receiver to remove debris is the first step in addressing this issue. Applying adequate lubrication to all moving parts can also prevent unnecessary friction. If certain components are out of spec, replacing them with high-quality alternatives can restore smooth operation.

Mil-Spec and Testing Standards

When purchasing a BCG, understanding its construction and testing can help ensure reliability. Mil-Spec BCGs, like the ODIN Works AR-15 Black Nitride Bolt Carrier Group, adhere to stringent military specifications, making them compatible with a wide range of rifles. Magnetic Particle Inspection (MPI) and High-Pressure Testing (HPT) are common quality control measures. MPI uses magnetism to detect surface flaws, while HPT subjects the BCG to high pressures to verify its strength. These tests ensure durability and reliability, though some debate whether HPT can shorten a BCG’s lifespan.

At Dirty Bird Guns & Ammo, we prioritize providing reliable, high-quality bolt carrier groups that deliver exceptional performance. Maintaining your AR-15 Bolt Carrier Group is essential for reliability and performance. Regular cleaning, lubrication, and inspection can prevent many common issues. Using high-quality components and ammunition further enhances the rifle’s reliability and longevity. By understanding these common problems and their solutions, you can ensure your AR-15 functions flawlessly when you need it most.

A question ar 15 you shoot a round it rejects the spent round but will not put another round in the chamber but it resets the firing pin what is causing this ?

We’d test mags first before going further.